Un filtro de jeringa (a veces llamado filtro de rueda si tiene forma de rueda) es un cartucho de filtro de un solo uso. Se adjunta al final de una jeringa para su uso. Los filtros de jeringa pueden tener accesorios de bloqueo Luer, aunque no universalmente. El uso de una aguja es opcional; Cuando se desee, se puede colocar en el extremo del filtro de la jeringa.

Un filtro de jeringa generalmente consiste en una carcasa de plástico con una membrana que sirve como filtro. El líquido a purificar puede limpiarse extrayendo la jeringa a través del filtro, o forzando el líquido sin filtrar hacia afuera, a través del filtro.

Características de los productos+

|

GF13070 |

Filtro de jeringa, 13 mm, 0.70um, fibra de vidrio |

|

GF13100 |

Filtro de jeringa, 13 mm, 1.00um, fibra de vidrio |

|

GF17070 |

Filtro de jeringa, 17 mm, 0.70um, fibra de vidrio |

|

GF17100 |

Filtro de jeringa, 17 mm, 1.00um, fibra de vidrio |

|

GF25070 |

Filtro de jeringa, 25 mm, 0.70um, fibra de vidrio |

|

GF25100 |

Filtro de jeringa, 25 mm, 1.00um, fibra de vidrio |

|

GF30070 |

Filtro de jeringa, 30 mm, 0.70um, fibra de vidrio |

|

GF30100 |

Filtro de jeringa, 30 mm, 1.00um, fibra de vidrio |

Technical Information+

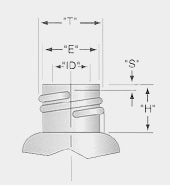

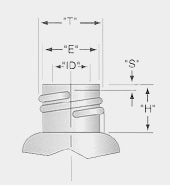

Vial Finish Specifications

Screw Thread Finishes

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Typical GPI finishes found in the chromatography field are as follows:

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Glass Technical Information

Borosilicate - A glass that is high in silicate and having at least 5% boron oxide.

Linear Coefficient of Expansion - Fractional change in length of glass per degree change in temperature.

Strain Point - Maximum temperature to which glass should be heated during use"

Types of Glass:

USP Type - Pharmaceutical glass containers can be classified as USP Type I, II, III or NP.

Type I - Borosilicate glass represents the least reactive glass.

Type I glass has the least pH shift. (Lowest leaching characteristics) Coefficient of Expansion = 33 or 51 for Clear and 51 for Amber

Type II - is de-alkalized soda lime glass with higher levels of sodium hydroxide and calcium oxide.

Type III - soda lime glass - cannot be autoclaved.

Type NP - general purpose soda-lime glass used where chemical durability and heat shock are not factors.

Coefficient of Expansion = 92.

GLASS PROPERTIES

| Color |

Clear |

Amber |

|---|---|---|

|

Linear Coefficient of Expansion |

33 |

51 |

|

Strain Point (Degrees Celsius) |

515 |

535 |

|

USP Class Type |

Type 1 |

Type 1 |

|

Light Protection |

No |

Yes |

Plastic Properties

| Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic |

|---|---|---|---|---|---|

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

Process Flow Diagram+

The workers clean the tubing with cloth

The workers plug the tubing into machine for making vials

The vials are transferred to QC for Physical Test

The workers put the tested vials into one big package (500-800pcs/pack)

The workers get the vials from big package and put the vials into one special tray.

Put the tray with vials into the Water injection machine

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The vials in tray will be transferred to Jilt water machine.

The vials in tray will be transferred to Infrared drying case.

The workers will collect the vials after vials are dry.

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The workers will check all the vials inclouding the bottom neck ,bottom ,inerts.

The workers will pack 100pieces vials into one package.

The workers will send the package to sealing machine for packing.

FAQ+

Forms

In scientific applications, the most common sizes available are 0.2 or 0.22 µm and 0.45 µm pores. These sizes are sufficient for HPLC use. The smallest known sterile syringe microfilter have pore sizes of 0.02 µm. Membrane diameters of 10 mm, 13 mm, 25 mm are common as well. Some syringe filters for small volumes may not resemble a wheel at all.

The syringe filter body may be made of such materials as polypropylene and nylon. The filter membrane may be of PTFE, nylon, or other treated products for specific purposes. Most manufacturers publish compatibility wallcharts advising users of compatibility between their products and organic solvents or corrosive liquids (e.g. trifluoroacetic acid).

Application

Syringe filters may be used to remove particles from a sample, prior to analysis by HPLC. Particles easily damage an HPLC due to the narrow bore and high pressures within. Syringe filters are quite suitable for Schlenk line work, which makes extensive use of needles and syringes (see cannula transfer). Being relatively affordable, they may be used for general purpose filtration, especially of smaller volumes where losses by soaking up filter paper are significant.

Syringe filters are also available for the filtration of gases, and for the removal of bacteria from a sample.

Disk filters are frequently used for the onsite manufacture of parenteral drugs and sterile eye drops, in order to remove microbiological contaminations (sterile filtration).[1]

Harm reduction in recreational drug use

Syringe filters may be used to filter solid drugs (powder and pill forms for example) prior to injection. Commonly filtered recreational drugs include heroin, methadone (Physeptone - See below), amphetamines, ecstasy or benzodiazepines. The filter still lets the drug through, but gets rid of many impurities such as fungal spores, bacteria or 'filler' used in the drug. Filters with 0.1 µm compared with 0.2 µm pore size have enhanced bacterial removal according to a study.[2] The use of wheel filters is strongly recommended when illicit drug users seek to inject prescription medications such as morphine and benzodiazepines that come in tablet form. However it should be noted that some benzodiazepines, such as diazepam, have only a very slight solubility in water, so there may potentially be no more benefit gained from injecting a diazepam tablet, even with a filter, than swallowing it. For the best advice on injecting such tablets, information should be sought from a harm reduction service with a good knowledge of the drugs that "wheel" filters are best used for. If, however, you feel that you must inject crushed diazepam tablets, (despite the fact that there is potentially no difference in the effect gained from the drug), it is much safer to use a filter than nothing at all, as the potential for particles to become lodged in veins or arteries carries serious health risks.

Pills like prescription opiates or benzodiazepines which are often converted by users into crude injectables, have ingredients such as chalk and wax as a 'filler', and illicit drugs are often adulterated with fillers to increase profits. Correctly used, wheel filters with at least pore size 0.5 µm may reduce these impurities entering the blood stream and help avoid vein problems such as collapsed veins, abscesses, infections, embolism, 'dirty tastes', disease and septicemia.[citation needed]

While wheel filters are the most effective filter available for injecting drug users along with luer lock syringe tip filters, other more common types of filters used include cotton wool, tampons, and cigarette filters. While these can serve as basic filters, they have a greater risk of bacterial infection or contamination from pieces of the filter itself. The condition known as cotton fever is caused by cotton used as a filter.

Inquiry

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible. ( * is required information)

¿TIENE ALGUNA PREGUNTA SOBRE NUESTROS PRODUCTOS?

CONTACTO