Filtro de jeringa (también llamado filtro-rueda si tiene la forma de rueda) es un cartucho de filtro de un solo uso, que se fija al extremo de una jeringa. Filtros de jeringa pueden tener conectores para cierre Luer, pero que no universalmente. Uso de aguja es opcional; cuando sea necesario, puede colocarla al extremo del filtro de jeringa.

Filtro de jeringa normalmente consiste de una carcasa de plástico con membrana que sirve como un filtro. Si un líquido exige depuración, tírelo a través de una jeringa o exprímalo hacia fuera de una jeringa a través de un filtro.

Características del producto+

|

MCE13022 |

Filtro de Jeringa, 13mm, 0.22um, Selulosa Mixta |

|

MCE13045 |

Filtro de Jeringa, 13mm, 0.45um, Selulosa Mixta |

|

MCE17022 |

Filtro de Jeringa, 17mm, 0.22um, Selulosa Mixta |

|

MCE17045 |

Filtro de Jeringa, 17mm, 0.45um, Selulosa Mixta |

|

MCE25022 |

Filtro de Jeringa, 25mm, 0.22um, Selulosa Mixta |

|

MCE25045 |

Filtro de Jeringa, 25mm, 0.45um, Selulosa Mixta |

|

MCE30022 |

Filtro de Jeringa, 30mm, 0.22um, Selulosa Mixta |

|

MCE30045 |

Filtro de Jeringa, 30mm, 0.45um, Selulosa Mixta |

Technical Information+

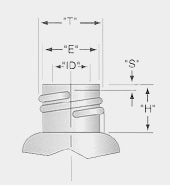

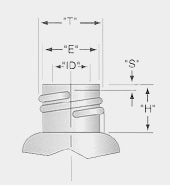

Vial Finish Specifications

Screw Thread Finishes

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Typical GPI finishes found in the chromatography field are as follows:

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

GPI refers to the "Glass Packaging Institute"

The GPI is responsible for establishing and issuing standards for the types and finishes produced by American glass manufacturers.

Glass Technical Information

Borosilicate - A glass that is high in silicate and having at least 5% boron oxide.

Linear Coefficient of Expansion - Fractional change in length of glass per degree change in temperature.

Strain Point - Maximum temperature to which glass should be heated during use"

Types of Glass:

USP Type - Pharmaceutical glass containers can be classified as USP Type I, II, III or NP.

Type I - Borosilicate glass represents the least reactive glass.

Type I glass has the least pH shift. (Lowest leaching characteristics) Coefficient of Expansion = 33 or 51 for Clear and 51 for Amber

Type II - is de-alkalized soda lime glass with higher levels of sodium hydroxide and calcium oxide.

Type III - soda lime glass - cannot be autoclaved.

Type NP - general purpose soda-lime glass used where chemical durability and heat shock are not factors.

Coefficient of Expansion = 92.

GLASS PROPERTIES

| Color |

Clear |

Amber |

|---|---|---|

|

Linear Coefficient of Expansion |

33 |

51 |

|

Strain Point (Degrees Celsius) |

515 |

535 |

|

USP Class Type |

Type 1 |

Type 1 |

|

Light Protection |

No |

Yes |

Plastic Properties

| Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic | Type of Plastic |

|---|---|---|---|---|---|

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

| Maximum use temperature, C/F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F | 80°C/176°F |

Process Flow Diagram+

The workers clean the tubing with cloth

The workers plug the tubing into machine for making vials

The vials are transferred to QC for Physical Test

The workers put the tested vials into one big package (500-800pcs/pack)

The workers get the vials from big package and put the vials into one special tray.

Put the tray with vials into the Water injection machine

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The vials in tray will be transferred to Jilt water machine.

The vials in tray will be transferred to Infrared drying case.

The workers will collect the vials after vials are dry.

The vials in tray will be transferred to next step for Ultrasonic oscillations.

The workers will check all the vials inclouding the bottom neck ,bottom ,inerts.

The workers will pack 100pieces vials into one package.

The workers will send the package to sealing machine for packing.

+

Inquiry

If you have any question or comment, please contact us without hesitation. We will reply you as soon as possible. ( * is required information)

¿TIENE ALGUNA PREGUNTA SOBRE NUESTROS PRODUCTOS?

CONTACTO